Alstom Transport Limited (ATL) was commissioned

to build a test track at Old Dalby, Leicestershire by developing an

existing, unused, non-electrified railway line. The primary use of the

track was to carry out testing of the new tilting trains to be run on

the West Coast Main Line.

The track was to be electrified at 25 kV, 50 Hz by feeding it from the

National Grid through East Midlands Electricity (EME) at 132 kV via a 10

MVA, 132 kV/25 kV single-phase transformer close to the existing RJB

Mining Ashfordby main intake substation end of the tests track. The new

substation was to be constructed on RJB land adjacent to its 132 kV/11

kV main intake substation.

The existing substation has two separate 132 kV/11 kV distribution

transformer feeders. These feeds are tapped from the primary side of the

132 kV/11 kV transformers to feed two 132 kV/25 kV transformers in the

new Old Dalby test track substation. Each of the two 132 kV/25 kV

transformers is connected to a different 132 kV feeder line. They are

interlocked so that only one supplies the test track at any given time

whilst the other remains on standby. Since the substation will be 1.1 km

(0.66 mile) away from the test track, there is a 25 kV wooden pole

overhead line that conveys the supply to the test track via a trackside

feeder station.

Turner Townsend Project Management was already involved in the on-site

buildings construction and PB was requested to assist them as technical

advisors in respect to railway mechanical and electrical issues.

The Objective

The challenge was to achieve power available and energised to the test

track in less than six months. Hence, there was a need to stage the

works because the complete and final design implementation would not be

possible before the desired end date. If the energisation date was not

met, then embarrassment together with possible financial penalties might

have occurred in accordance with the agreed contract for the supply of

the class 390 trains.

The main requirement, therefore, was a suitably rated power supply of

sufficient provision, with standby or backup facilities, to run a number

of Class 390 trains up and down a test track of 17.5-km (10.5-mile)

length. The same supply would also be used to stable and manoeuvre

trains in the light maintenance depot. A latter requirement added

thereafter was verification of electromagnetic compatibility (EMC) and

electromagnetic immunity (EMI) issues between the traction power supply

and signalling equipment that would now be housed in the light

maintenance depot. Primarily it was not envisaged to introduce the

catenary’s 25 kV power supply into the building and, hence, the vicinity

of the signalling control centre.

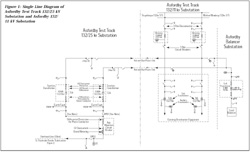

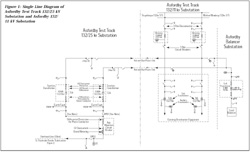

Figure 1: Single Line Diagram of Asfordby Test Track 132/25 kV

Substation and Asfordby 132/11 kV Substation |

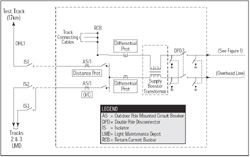

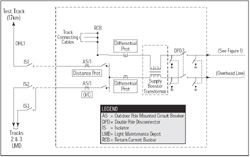

Figure 2: Asfordby Test Track Feeder Station |

Table 1: Interface Responsibilities

|

Design Concept

By the time we were invited to participate as advisors and design

checkers, the contractor, Alstom Transmission and Distribution Ltd.

(AT&D) had already provided the preliminary draft design diagram and

equipment support information to the client, ATL, as a proposal. The

traction power transformers were already on order. That meant the

overall design needed to be actually ongoing and developed during the

tight program schedule.

For this unorthodox approach, a co-operative and co-ordinated team

effort would be required from all partners—from the simulation and

modelling specialists through to the various contractors operating on

site. Our team managed the co-ordination of the design development,

producing interface responsibilities and chairing technical meetings

with the parties involved to that end.

The single line diagram in Figure 1 shows how the 25 kV power supply is

derived from the 132 kV tower at the RJB intake substation and delivered

via a 1.1-km (0.66-mile) overhead transmission line to the trackside

feeder station (Figure 2). The interface matrix provided in Table 1 on

the following page gives an idea of the companies involved and their

respective responsibilities, as co-ordinated by PB.

Development and Stages of the Work

Time was of the essence in terms of providing a supply to the test track

in a few months, so it was necessary to work on the basis of

implementing various installation stages in line with equipment

availability and EME/RJB permitted outages. Stage 1 had to involve a

direct bus connection to the primary side of RJB’s 132 kV/25 kV

distribution transformer that temporarily relied on protection through

an existing fault thrower backed up by the EME network. Other stages

were planned to connect the standby traction power transformer and its

associated equipment, as well as the developments described below.

132 kV Metering. It became apparent during

design/co-ordination meetings that commercial metering of the supplies

could not take effect at 25 kV, as this would involve a second user. RJB

owned the site and already had an agreement with EME, so only one or

sole user would be legally acceptable. Metering would have to take place

at 132 kV, meaning additional switchgear and protection would be

necessary, as shown in Figure 1. This development placed added pressure

on the design and installation phases and constituted a second

installation stage. Furthermore, check metering was also included to

assist in the monitoring of consumption relative to the test track.

Problems Due to Negative Phase Sequence. Studies and

measurements by EME showed existing high, out-of-phase, negative phase

sequence phenomena on their network. The introduction of the traction

loads from the test site would exceed the recommended requirements of

Engineering Recommendation (ER) P24 when added to the existing

background levels. The fault level at the Asfordby main intake

substation was significantly low enough to maintain a negative phase

sequence that was above the requirements.

One option was to install a new 132 kV grid site in the vicinity to

increase the fault level. This solution would take at least five years

in terms of planning, design and installation, however, so did not

provide a remedy in the short term. Phase balancers, although less

expensive in relation to a new grid site but known for their

effectiveness, were considered as an alternative. There was sufficient

space adjacent to the RJB mining 132 kV/11 kV substation site.

Therefore, another future but final installation stage would need

consideration.

Introduction of Phase Balancing. The design principle

and objective of a phase balancing system is to eliminate completely the

negative phase sequence currents by adding one or more other

single-phase loads. The most orthodox or obvious way of achieving this

and correcting the unbalance that results from a single-phase load is to

equalise the three phases by adding appropriate single-phase loads into

the other two phases. This is not easy to achieve practically,

especially for a variable or dynamic load. The real and reactive power

of the traction load must be monitored and then the appropriate control

signals generated to the thyristor controlled reactors. This will then

provide the required value of reactive power output in each phase.

Independent control of each phase of the balancer is needed to obtain

the necessary correction of the single-phase load.

Phase balancers generally take about 18 months to design and manufacture

from when the various technical parameters are known. The size and

layout of the equipment is quite formidable. Fortunately, there was

knowledge of an existing balancer that could be modified and adapted,

thereby having the advantage of reducing some of the lead-time.

Connections for the phase balancer are shown in Figure 1.

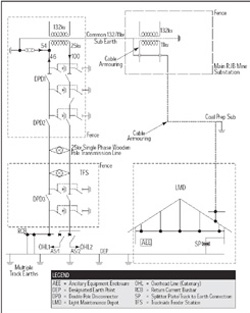

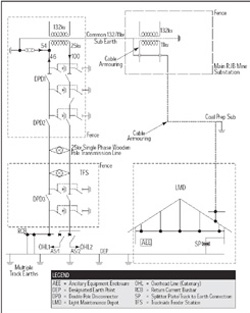

Earthing and EMC Issues Within the Area of the Light Maintenance

Depot. The 25 kV overhead line catenary power supply was

originally going to be wired up to a distance remote from the light

maintenance depot. The building’s internal services would be in

accordance with and signed off as compliant with the IEE regulations.

Later requirements dictated that the 25 kV traction power supply would

be brought into the building, however. The signalling and

telecommunications engineers then raised concern over this change of

requirement because their equipment, which was originally designed to be

housed in rooms within the light maintenance depot, might now be

subjected to potential traction faults in terms of touch voltages and

EMI/EMC issues.

Power Up and Tests. A test procedure document and test

plan was conceived by PB in advance of the power-on date and made

available to the client and the relevant disciplines. Stage one of the

power supply design was completed on time, prior to delivery of the

first vehicle for ceremonial use. Power was switched on in a controlled

manner late at night via an approved switching procedure involving PB,

EME Border (overhead catenary installation specialists) and AT&D, the

main mechanical and electrical power supply equipment designer and

installer.

Load Tests. Although one of the Class 390 vehicles was

delivered and thus perceived available for initial load tests,

sufficient steady load in terms of continuous current could not be

successfully drawn. A contributory factor was the not-fully-commissioned

lighting, air conditioning and heating that could have provided the

appropriate minimum “pick up” values and thus prove the protection

relays. This problem was rectified and verified at a later date along

with other measurements to satisfy the EME and ATL.

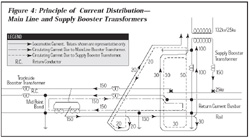

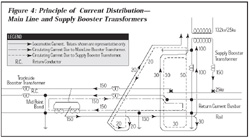

Figure 3: Principle of Current Distribution - No Booster

Transformers |

Figure 4: Principle of Current Distribution - Main Line and

Supply Booster Transformers |

Figure 5: Distribution of Percentage Traction Current Prior to

Insertion of Mains Booster Transformer |

Mains Supply Booster Transformer.

Initial current measurements revealed that a larger than normal

percentage of return current was travelling back to the substation via

11 kV cable sheath earths in the vicinity of the light maintenance depot

and RJB’s coal preparation plants. Earth return currents may share up to

15 percent to 20 percent of the total current delivered by the

substation site. Although load currents were low due to the use of a

non-fully-commissioned train’s auxiliaries static load, a 54 percent

share of the return current via earth was ascertained by current

measurement transformers, with only 46 percent flowing back in the

return conductor path (Figure 3). A means to overcome this phenomenon

had to be developed and applied in the medium term before the loads

became significant.

A supply booster transformer has the capability of encouraging the

return currents to flow in the return current system (Figures 4 and 5).

Although other power supply isolation methods were considered, this

option proved to be more economic and less disruptive. A supply booster

transformer was thus acquired and installed inside the trackside feeder

station immediately after the completion of stage one. This application

was successful in performing the desired effect and encouraged the

currents to flow through the orthodox return current conductor system

route.

Technology Impact

Strictly speaking, the technology used in the design applications does

not have an impact, as such, on PB because it is generally included

within the human resource and expertise of its personnel. One could

argue, however, that there is an impact in the sense that working with

this technology broadens or bolsters our experience base. The impact of

the technology to the project is, for example, in the introduction of a

mains booster transformer, paramount in finalising a successful design

whilst being cognisant of safety and economics. Moreover, such elements

of this technological know-how contributed “added value” to the project.

There were no “new” technical developments to be perceived as such, but

the introduction of the mains supply booster transformer and the phase

balancer, the resolution of the earthing issues and how they came about

were innovative on the part of our key team members. Particularly unique

was the fact that all this phenomena occurred on the same project and

under very tight time scales for resolving such issues.

The Future

At the time of writing, there are still the remaining design stages yet

to take effect. Stage 2 involves the installation of the second traction

transformer, 2-phase 132 kV circuit breakers and 3-phase 132 kV circuit

breakers with their metering facilities. A final stage will include the

installation of the phase balancer. These remaining stages are currently

ongoing and will run on until the end of the year, thereafter to provide

what is perceived to be a reliable and secure power supply, not only for

the testing of tilting trains but also for the variety of other vehicles

that come off the production line. Moreover, a British test site will be

available to put them through their paces.

End Note

Hopefully, this article is helpful and interesting for those working not

only in the area of traction power supply, but also for those involved

in the realms of technical project/engineering management. Our team was

interfacing with a variety of contractors and designers who all worked

extremely hard

to satisfy the client’s requirements. |